Download Ebook Prober Manual P12 to get free Nook books as well as other types of ebooks. Prober Manual P12 Prober Manual P12 Prober Manual P12 This is likewise one of the factors by obtaining the soft documents of this Prober Manual P12 by online. You might not require more become old to spend to go to the books creation as capably as search. Accretech's high-end 200mm prober, the UF2000 does not have the broad acceptance like the orignal UF200 platform. Please contact us to verify availability, configuration requirements and pricing. It is the prober with high-speed probing that targets non-memory device. Probing Machine: UF2000 Most significant machine model for 200mm wafers High precision, high rigidity machine.

The following tools are currently being used:

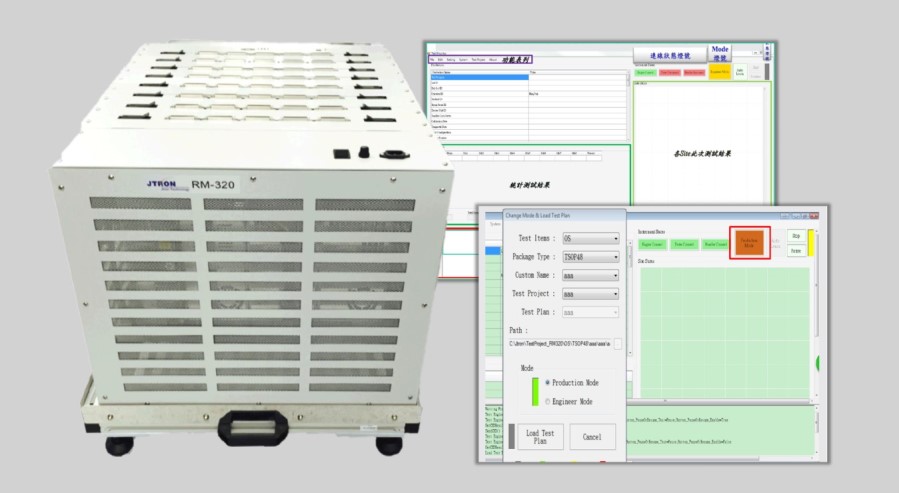

Facilities for Functional Test on Integrated Circuits

288 digital channels (256 providing up to 800Mb/s datarate, 32 providing up to 1.6Gb/s)

4.1GS arbitrary waveform generator

320MS/1GHz digitizer

1x 8 channel device power supply (max 4A/channel)

2x 4 channel device power supply (max 8A/channel)

Additional software for memory test and scan test analysis

Supports manual package test and automatic wafer test (using the UF200 wafer prober)

Accretech UF200 wafer prober

Fully automatic wafer prober for up to 25 wafers/lot

Supports 6inch and 8inch wafers

Temperature controlled chuck, -40°C up to +125°C

256 digital channels (up to 125MHz)

4-channel Agilent power analyser

1 system configured for package test, the other system configured for wafer test

Tsk Uf200

Accretech UF200A wafer prober

Standard chuck (not temperature controlled)

Spectral range 7.5 .. 14µm

Temperature measurement range -40°C .. 1200°C

Image size 640x480

Standard lens 1.0/30 mm

Tsk Uf200 Prober Manual

image area (30 x 23)°,

minimum distance 300mm

Microscope objective 1,0x

image (16 x 12) mm²,

Uf200 Prober Manuals

distance 50 mm, resolution 25µm

Online: up to 10 points

Offline: temperature of each pixel can be determined, additionally regions with min/max evaluation can be defined

Usage: e.g. detection of hot spots on chips (caused by shorts), thermal check of PCBs, etc